Plastic Parts Direct have been tasked with producing a complex automotive moulding using 4 hydraulic core pulling devices to produce internal features on a part not feasible by straight forward ‘open and shut’ tooling.

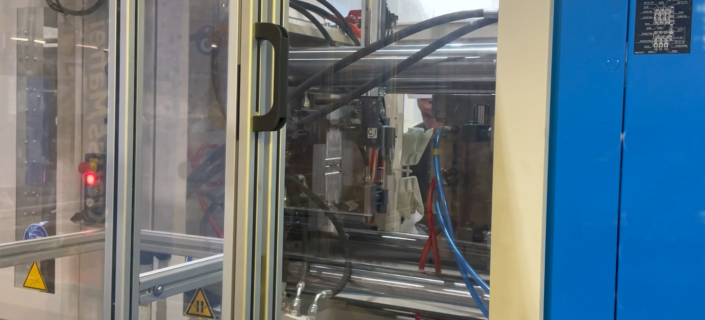

The tool is being trialled on a Krauss Maffei 160 tonne CX machine to exacting standards with 4 cores being operated whilst the mould tool is closed. A pick and place operation via a Whittmann Primus 16 robot is utilised to handle the finished product.